In 2018, the Chinese tech giant Foxconn caused a stir when it replaced 60,000 of its factory workers with robots. Since then, artificial intelligence (AI) has been making significant inroads into the manufacturing sector. Today, a visit to a manufacturing unit reveals a scene that’s slightly different from what it used to be. Machines whir and hum, producing high-quality components while a team of engineers monitors their progress on a bank of screens, using AI algorithms to optimize production and detect potential faults before they occur. From predictive maintenance and quality control to supply chain management and product design, AI in manufacturing industry transforming the way we make things.

AI technology is being utilized to analyze massive amounts of data, identify patterns, make informed decisions and predictions, enhance efficiency, and provide personalized experiences to users. But what exactly is the role of AI in manufacturing, and how is it changing the industry? In this article, we will explore the latest trends and developments in AI-powered manufacturing and look at how these technologies are likely to shape the future of the industry.

The Revolution of AI in Manufacturing Industries

The application of AI in manufacturing can play a critical role in achieving business success and maintaining competitiveness in a constantly evolving landscape. By leveraging AI, manufacturers can uncover new insights and opportunities for innovation that enable the development of new products and processes to set them apart from their competitors.

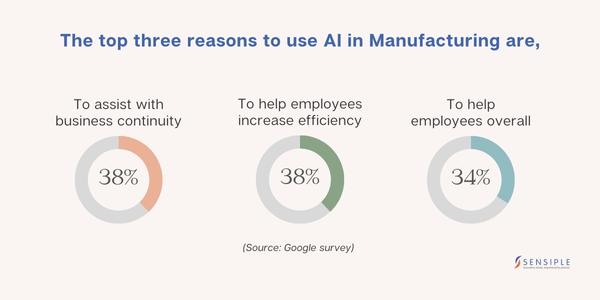

AI-powered machines and systems have the potential to boost operational efficiency, reduce labor expenses, and enhance product quality in the manufacturing sector. Additionally, implementing AI can optimize resource management, minimize wastage, and improve the overall customer experience.

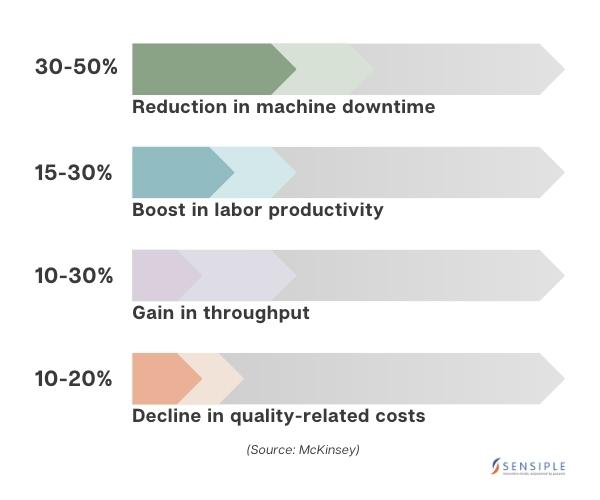

According to McKinsey, the integration of AI, machine learning, and robotics into manufacturing constitutes the Fourth Industrial Revolution. These advanced manufacturing technologies offer significant benefits in terms of operating costs, efficiency, and productivity.

AI Driving Growth and Innovation

AI reshapes the manufacturing industry with:

Predictive Maintenance: AI algorithms can detect and prevent equipment breakdowns, minimize downtime and increase efficiency.

Quality Control: AI can identify defects, ensure adherence to standards, improve product quality, and reduce waste.

Supply Chain Optimization: AI can optimize the supply chain, reduce lead times and increase efficiency to stay competitive.

Robotics and Automation: AI-powered robots can improve operational efficiency and reduce labor costs.

Demand Forecasting: AI algorithms can forecast demand, minimize waste and maximize profitability.

Danone achieved a 20% reduction in forecast errors and a 30% decrease in lost sales through implementing ML demand forecasting.

The Significance of AI in Manufacturing: Why it is Critical for the Future

Each manufacturer strives to discover novel approaches to cut costs, increase profits, mitigate risks, and enhance overall manufacturing effectiveness. It transforms the traditional manufacturing process by improving efficiency, productivity, and quality. According to a report by Microsoft in October 2019, Manufacturing companies that adopted artificial intelligence (AI) outperformed their competitors, with a reported 12 percent increase in performance.

Artificial Intelligence in Manufacturing Industry can create personalized products based on customer data, reduce waste and energy consumption, decrease the carbon footprint, and prevent accidents and injuries.

Using machines equipped with computer vision allows for observing and monitoring operations without human intervention.

AI in manufacturing with process automation leads to:

- Reduced cycle times

- Increased accuracy

- Higher production output

Moreover, Automation can help boost employee morale and productivity by freeing them from repetitive and monotonous tasks. A report by McKinsey suggests that implementing AI for process automation can increase yield by up to 30% and decrease scrap rates and testing costs.

The Competitive Edge: AI Use Cases

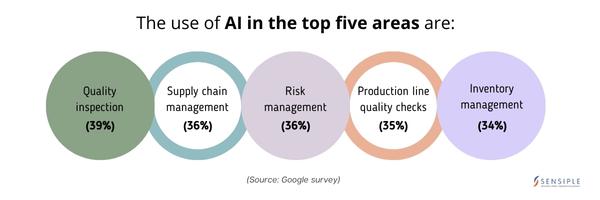

The manufacturing industry can derive significant benefits from using artificial intelligence, particularly in planning and production floor operations. Based on a BCG report, the most important AI use cases in Manufacturing are:

- Implementation of intelligent and self-optimizing machines to automate production processes

- Forecasting efficiency losses to improve planning

- Detection of quality defects to enable predictive maintenance

In short, AI can make a significant difference in Manufacturing. Companies can reduce errors and lost sales by using machine learning to predict demand. Process automation using computer vision can speed up operations, improve accuracy, and increase productivity while making tasks less boring for employees. According to McKinsey, AI can even help increase yield and reduce costs. So, it’s clear that AI has the potential to revolutionize the manufacturing industry and make it more efficient and profitable.

How Sensiple can help:

AI-led Google Cloud platform prioritizes serving the manufacturing industry, providing solutions that enable revenue growth, operational excellence, and innovation throughout the manufacturing value chain. With the help of Google Cloud, manufacturing companies are leveraging enormous amounts of data to make informed business decisions, reduce costs, and speed up their time-to-market.

At Sensiple, we make the most of our expertise honed by more than 22 years in the Information Technology domain to design solutions that perfectly fit your needs. We prioritize unmatched security, advanced features, and user-friendly functionalities while creating solutions on top of cutting-edge platforms.

Combining our deep understanding of technology and a comprehensive understanding of your business needs, we can guide you toward implementing the most appropriate Google Cloud AI solution for your manufacturing operations. Contact us at info@sensiple.com.